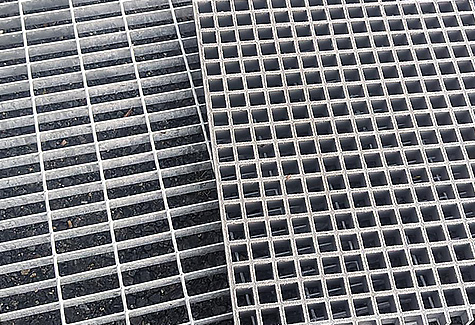

Selecting the right grating for your project is a critical decision that can significantly impact its performance, safety, and longevity. With a variety of grating materials and types available, making an informed choice is essential. In this blog we'll run through the key factors to consider when choosing the perfect grating for your specific project needs.

- Material matters: The first and foremost decision in choosing grating is the material. The most common options are Steel, Aluminium, and Glass Reinforced Polyester (GRP). Consider the specific requirements of your project, such as load-bearing capacity, corrosion resistance, and durability. GRP excels in corrosion resistance and durability. Understanding your project's needs will help you choose the right material.

- Load-bearing requirements: Determine the load-bearing requirements of your project, as grating is available in different thicknesses which have varying load-bearing capacities. Take a look at our load-bearing chart on our data sheets for further information on how span affects the load-bearing capacities.

- Environment: Consider the conditions your grating will be exposed to. If you are installing the grating in an environment where the external elements are demanding, such as near the coast or in an industrial setting with chemical exposure, corrosion-resistant materials like GRP may be the best choice. Environmental factors can significantly impact the grating's lifespan and performance.

- Safety and slip resistance: In environments where slip resistance is paramount our GRP grating is the choice for you. Our GRP grating is manufactured with a anti slip medium grit finish, which is designed to enhance safety, even in wet conditions, unlike steel, which can become hazardous in wet or oily environments. At Blue Diamond, we use The Pendulum Test, a method that accurately simulates real-world conditions to measure slip resistance. This ensures our surfaces meet the highest safety standards, providing accurate and reliable results to enhance safety and reduce slips, trips and falls. Our full grating range is pendulum tested, and our results consistently meet the highest level of slip resistance. We’re happy to provide copies of our certificates and further details on our comprehensive product testing programs should you require them.

- Installation and maintenance: Consider the ease of installation and maintenance. GRP grating can be easily cut to any size and is lightweight for convenient handling on site to ensure the best fit. In addition, GRP requires minimal maintenance compared to other options. Make sure you are aware of the project's timeline and budget to make the best choice.

- Budget considerations: Budget constraints are a reality for most projects. It's essential to balance quality and cost-effectiveness. While some grating materials might have a higher upfront cost, they can result in long-term savings due to reduced maintenance and longer lifespans. GRP is not only a cost-effective material, but it also brings additional cost savings to the project. Its lightweight nature contributes to lower transportation costs, while the ease of installation means lower labour expenses. In addition to this, GRP grating is a maintenance free solution which therefore means there are no associated costs with maintaining the material after installation. Coupled with its longevity surpassing that of steel, make it a wise choice.

- Customisation: GRP provides greater flexibility as it can be easily cut to any size or shape to suit any project requirement. Custom-sized grating can simplify installation and enhance the overall project efficiency.

In conclusion, choosing the right grating for your project is a decision that should be made with careful consideration of material, load-bearing capacity, environmental conditions, safety features, installation, budget, customisation, and compliance with local regulations. By considering these factors, you can select the right grating that ensures the success of your project while optimising safety, longevity, and cost-effectiveness.

If you need further guidance or have specific questions about grating for your project, don't hesitate to reach out to our team of experts. We're here to assist you in making the right choice and ensuring your project's success.